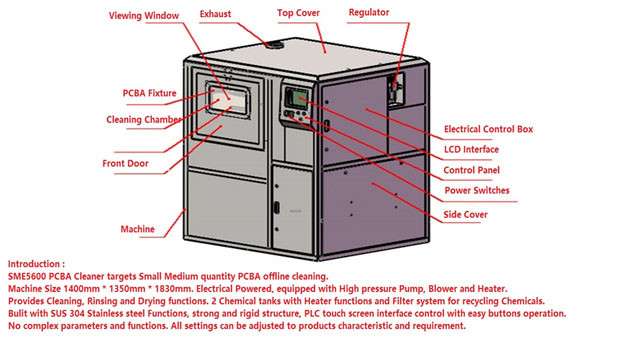

PCBA Cleaning Machine-SME-5600

- Model

- SME-5600

Item specifics

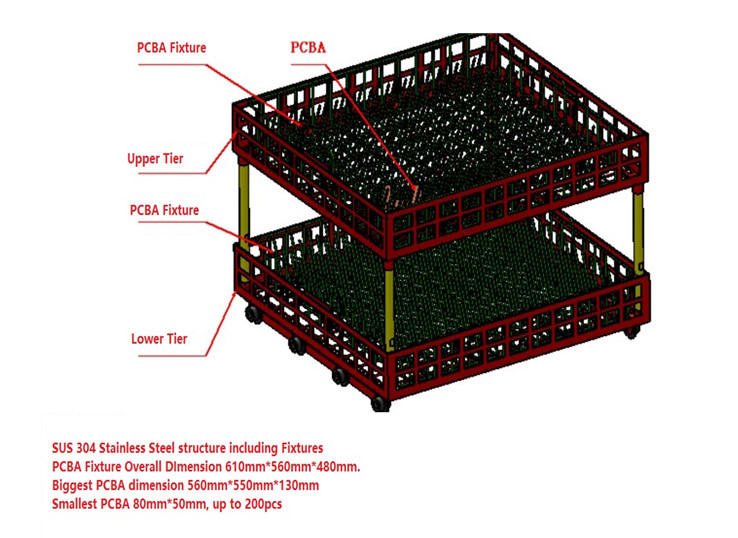

- Cleaning basket size

- 610mm(L)*560mm(W)*100mm(H)x 2 layers

- Concentration liquid tank capacity

- 30L

- Dilution tank capacity

- 60L

- Spray tank capacity

- 18L

Review

Description

PCBA Cleaning

Machine-SME-5600

Descriptions:

Features:

1. the whole process visible : the cleaning process can be visible

through the front window and LED light.

2. automatic cleaning mode: clean, rinse,

dry process can complete in one cabinet and compact machine.

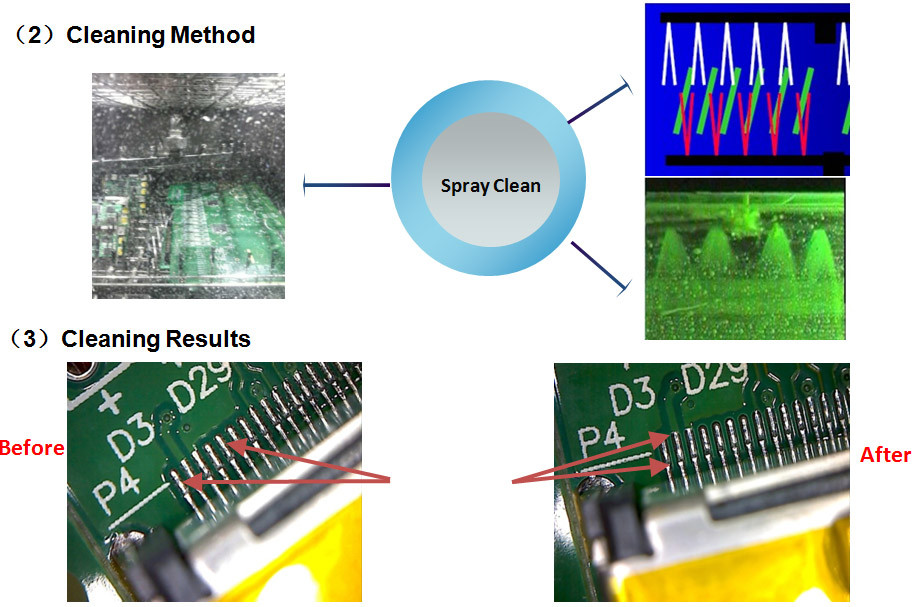

3. the most scientific nozzle design: the

use of left and right incremental distribution --- to enhance cleaning

efficiency,The upper and lower dislocation distribution - completely solve the

cleaning blind area;

4. the nozzle pressure adjustable design:

to solve the small and light PCBA in the high pressure spray under the

conditions of the collision, splash problem;

5. the standard dilution tank heating

system: greatly improve the cleaning efficiency. Shorten the cleaning time;

6. a comprehensive cleaning system: for

SMT; THT PCBA after welding the surface of the residual rosin, water-soluble

flux, no-clean flux / solder paste and other organic and inorganic pollutants

for thorough and effective cleaning;

7.

convenient cleaning dilution to add: can be manually added, but also by setting

the ratio (5% to 25%) automatically with DI water and chemical liquid (option);

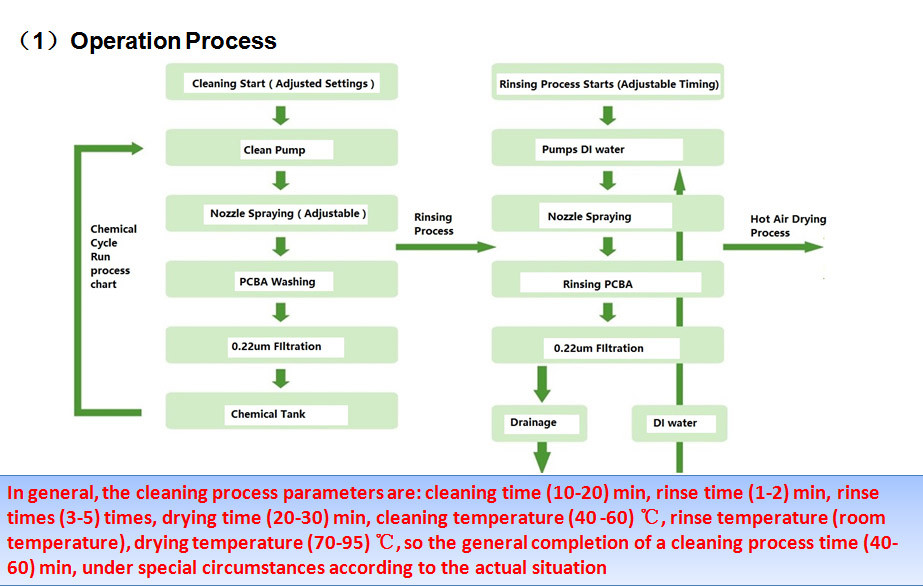

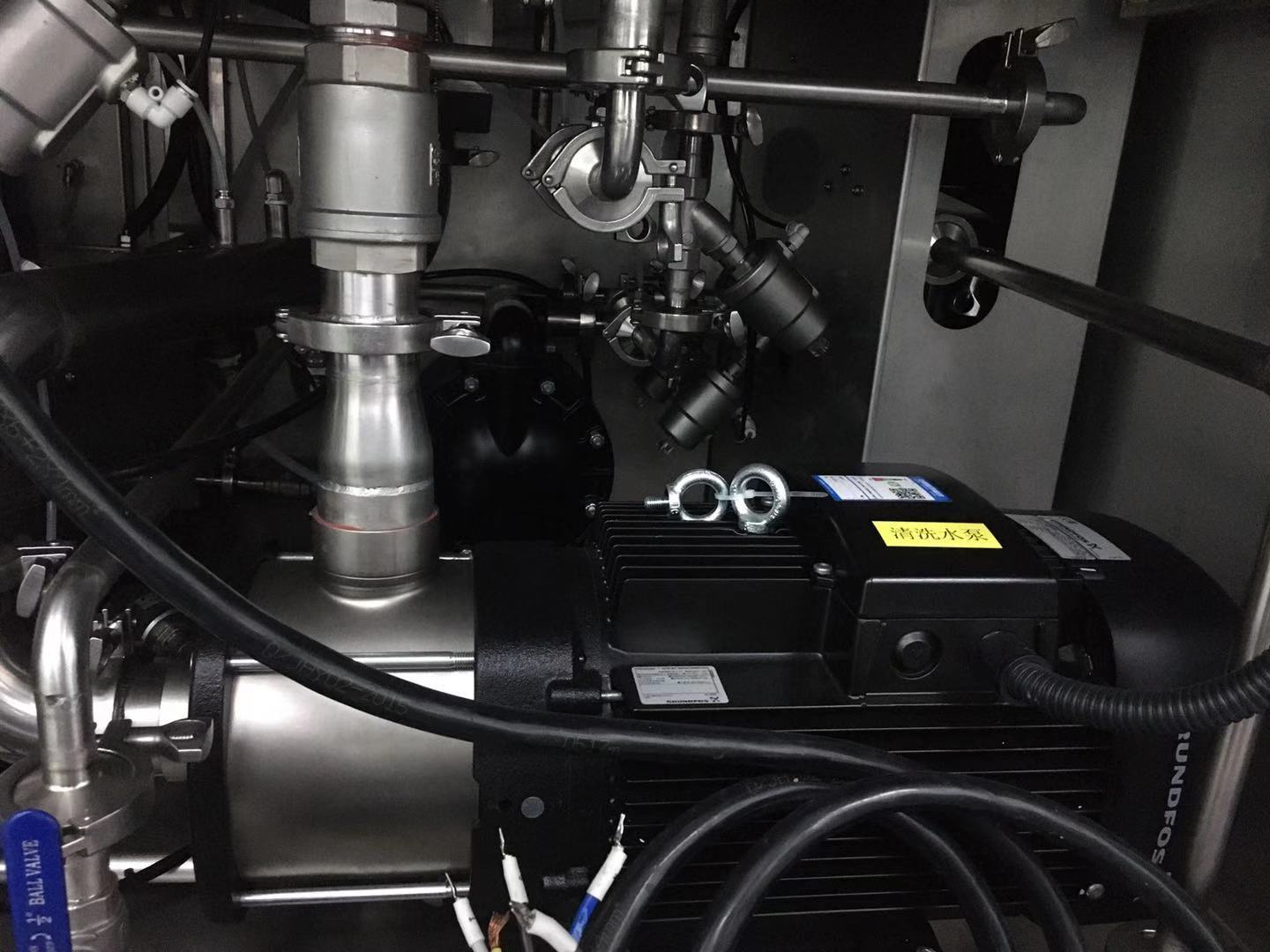

8.

Temporary tank and auxiliary heating system: Temporary tank is used to

store dilution and DI water.

During cleaning process, the air

pump absorb dilution form dilution tan and send to temporary tank ,then wash

pump absorb dilution from temporary tank to clean PCBA. After cleaning process,

the air pump absorb dilution from temporary tank and send them back to dilution tank.

During rinsing process, the air pump absorb DI water from DI water

produce machine and send it to temporary tank, each time after rinsing ,DI

water will be discharged form temporary tank. The rinse water can be heated as

needed;

9.

Lower operating costs: built-in filter makes the dilution repeated used. By

using compressed air blow method at the end of cleaning process : blow the

residual detergent off from pipeline and the pump , which effectively save 50%

dilution.

10.

The concentration lqiuid compensation function: the concentration of dilution

will be getting lower and lower after repeated use which will affect the

cleaning effect and cleaning efficiency of PCBA, at this time , need to add

some concentrated liquid to dilution

tank to compensate the dilution concentration. concentration compensation can

improve the effective use of liquid, the concentration liquid adding amount can

be adjustable according to the real situation.

Specifications:

|

Item |

parameters |

|

Cleaning

basket size: |

610mm(L)*560mm(W)*100mm(H)x

2 layers |

|

Concentration liquid tank capacity |

30L |

|

Dilution

tank capacity |

60L |

|

Spray

tank capacity |

18L |

|

Temporary

tank heater |

6KW |

|

Cleaning

time |

0~99min(adjustable) |

|

liquid

temp |

Room temp -75 degrees / (adjustable) |

|

Rinse

time |

1-99 times / 1~2min each time |

|

Rinse

water temp |

Room temp -75 degrees / (adjustable) |

|

Drying

time |

0 to 99 minutes / (adjustable) |

|

Resistivity

meter monitoring range |

0~18MΩ |

|

liquid

tank heater |

9KW |

|

Drying

Temperature: |

Room

Temp--99℃ /(Adjustable) |

|

Drying

Heater/KW: |

6KW |

|

Spray

Pressure: |

30PSI -

80PSI/(Adjustable) |

|

Chemical

liquid level filter: |

0.22μm

(filter microparticles: solder paste, rosin, flux and contaminants) |

|

DI water

Filter: |

0.22μm

(filter microparticles: solder paste, rosin, flux and contaminants) |

|

water

inlet: |

1 inch

fast junction interface |

|

Water

outlet: |

1 inch

fast junction interface |

|

Chemical

Inlet: |

1 inch

fast junction interface |

|

Real -

time pressure gauge: |

3PCS

(nozzle / DI water / waste liquid) |

|

pump: |

5.5KW |

|

Outlet

size: |

Φ100W)×30mm(H)

|

|

Power

source: |

AC380V

50HZ 65A/0.45MPa~0.7MPa |

|

Weight: |

600Kg |

|

Machine

Dimension: |

1300mm(L)×1200mm(W)×

1850mm(H) |

Company

Profile

About Samtronik

Samtronik is a professional one-stop SMT Equipment service

provider , With more than 10 years Electronic Manufacturing Service factory

Equipment selling experience .

Samtronik mainly supply pcb handling equipment ,PCB Separator

,screw locking machine , smt cleaning machine , smd counter , smd taping

machine ,smt parts etc .

Why Choose Us

1.We

promise customer response within 24 hours;

2. Well-trained and experienced staffs to answer

all your enquires in fluent English;

3.Best products and price to offer;

4.Shortest time to delivery the products ;

5.All machine will be strictly testing before

shipment;

6.OEM & ODM services offered;

7.Best Guarantee :With 1 years warranty !

Product

Packaging &Contacting Us