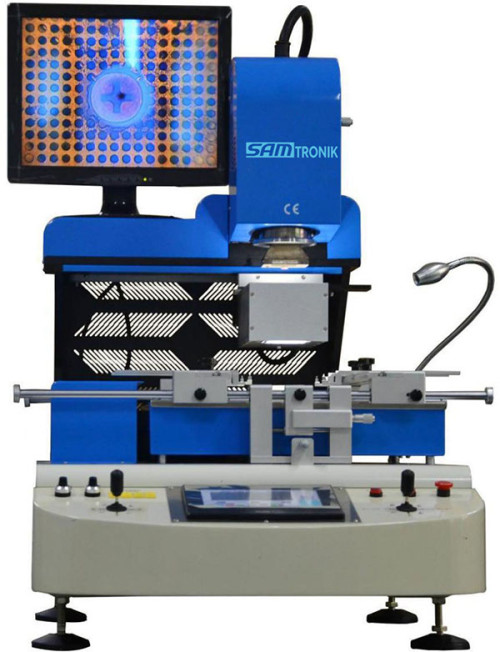

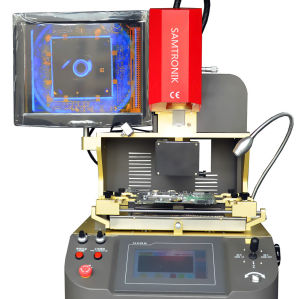

Automatic BGA Rework Station SM-750

- Model

- SM-750

Item specifics

- Application

- Automatic led panel repair

- Heating Type

- Hot air and Infrared

- Operation Type

- Software and Touch Screen Control

- Available BGA Chip

- BGA, QGN, QFN, Micro SMD, LED

Review

Description

l 5 working modes

l 15’’ HD LCD monitor

l 7’’ HD touch screen

l CCD color optical alignment system

l Laser light for positioning

l Infrared preheat tubes + hot air heating areas

l HD camera comes in & out automatically by button

l Temperature accuracy within ±1℃

l Mounting precision within ±0.01mm

l Repair success rate: 99% +

|

Power |

6800W |

|

Up heater

power |

1200W |

|

Down heater

power |

1200W |

|

IR heater

power |

4200W(2400W

control) |

|

Power supply |

(Single

Phase) AC 220V±10 50Hz |

|

Position way |

Optical

lens+ Vshape holder+laser positioning |

|

Temperature

control |

High

precision K shape sensor(Closed Loop),up and down independent

temperature heating zone,Precision can reach±1℃ |

|

Material |

High sensitive

touch screen+temperature control module+PLC+step drive |

|

PCB Size |

Max:500×450mm , Min: 10×10mm |

|

Thermo-couple

Ports |

4pcs |

|

Chips

magnification times |

2-30 |

|

PCB thickness |

0.5-8mm |

|

GA size |

0.8mm-8cm |

|

Min.chips

pitch |

0.15mm |

|

Mounting BGA

weight |

1000G |

|

Mounting

precision |

±0.01mm |

|

Overall dimension |

L670×W780×H850mm |

|

Optical

alignment lens |

Motor drive

can move front back right left |

|

Weight of

machine |

About 90kg |