PCBA In-line Cleaning Machine-SME-6200

- Model

- SME-6200

Item specifics

- PCBA max size

- 500mm(W)X100mm(H)

Review

- e

- 2025/11/18 20:56

e

Description

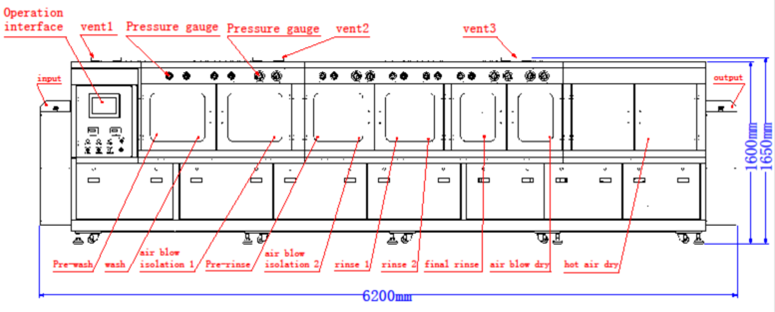

PCBA In-line Cleaning

Machine-SME-6200

Descriptions:

Features:

1. SME-6200 is a full SUS304 stainless steel system. All parts or frame of system which connect water and hot air are SUS304 material.

2. Mitsubishi PLC software control system,Touch panel operation interface, Chinese and English interface, easy operation.

3. 20 groups of cleaning procedures can be loaded out and saved in. Cleaning procedures can be edited quickly according to clean requirements.

4. Machine historical faults information can be checked at any time.

5.Upper and lower nozzles spray pressure of each set can be adjusted individually to achieve best spray cleaning effect.

6. Air knives’angle of each set can be adjusted to achieve best air blow effect.

7. The combination of high pressure jet clean and water curtain clean to cover clean pressure and penetration clean section and rinse section to achieve better cleaning result.

8. High quality, high pressure vertical pump, clean and rinse water pressure up to 120PSI.

9. By adopting overflow design on rinse sector, fresh DI water overflows from back side to front side to replace used DI water to ensure clean quality and save DI water.

10. Machine automatic starts to supply fresh DI water after cleaing subject arrives at rinse section--save DI water.

11. The system has energy-saving mode: this system is equipped with light curtain sensor at the input side. The system will stop working automatically when no PCBA are put in over setting time (for example over 15 minutes) to achieve water and energy saving function.

12. Rinse DI water quality resistivity monitoring system. Machine will alarm when detecting DI water resistivity value is less than setting value. This function reminds to replace DI water to ensure constant and good cleaning quality.

13. PCBA input and output light curtain sensor detecting sensor are equipped at input and output side. If plates has put out in setting time, machine will alarm to remind operators to check it out.

14. Net conveyor speed adjust by Inventor: Conveyor net speed is adjusting through inventor.more convenient.

15. Dual pressure meters system, the front meters are used for watching machine status, the rear meters are used for machine maintenance.

16. Air knives pressure can be adjusted according to requirement.

Specifications:

(1). PCBA max size: 500mm(W)X100mm(H)

(2). PCBA min size: 50mm(W)X50mm (need jig to fix because of high spray pressure)

(3). Conveyor net height: 100mm max

(4). Cleaning width: 500mm

(5). Conveyor mode: Net conveyor system

(6). Conveyor speed: 0.1-1.5m/min(adjustable),recommend 0.1~0.4m/min

(7). Conveyor direction: From Left to Right

(8). Noise: about 80 db

(9). Compressed air supply: 0.45~0.7MPa, less than 200L/Min

(10). Real power: 108KW when machine starting, about 90KW in normal working.

(11). DI water consumption: 10~15L/Min(water resistivity≥10 MΩ)

(12). Total air displacement: 40m³/Min(air exhaustion system supply by customer)

(13). Machine outline: 6200mm(L)x1650mm(W)x1650mm(H)

(14). Net weight: about 3000KG.

Company

Profile

About Samtronik

Samtronik is a professional one-stop SMT Equipment service

provider , With more than 10 years Electronic Manufacturing Service factory

Equipment selling experience .

Samtronik mainly supply pcb handling equipment ,PCB Separator

,screw locking machine , smt cleaning machine , smd counter , smd taping

machine ,smt parts etc .

Why Choose Us

1.We

promise customer response within 24 hours;

2. Well-trained and experienced staffs to answer

all your enquires in fluent English;

3.Best products and price to offer;

4.Shortest time to delivery the products ;

5.All machine will be strictly testing before

shipment;

6.OEM & ODM services offered;

7.Best Guarantee :With 1 years warranty !

Product

Packaging &Contacting Us