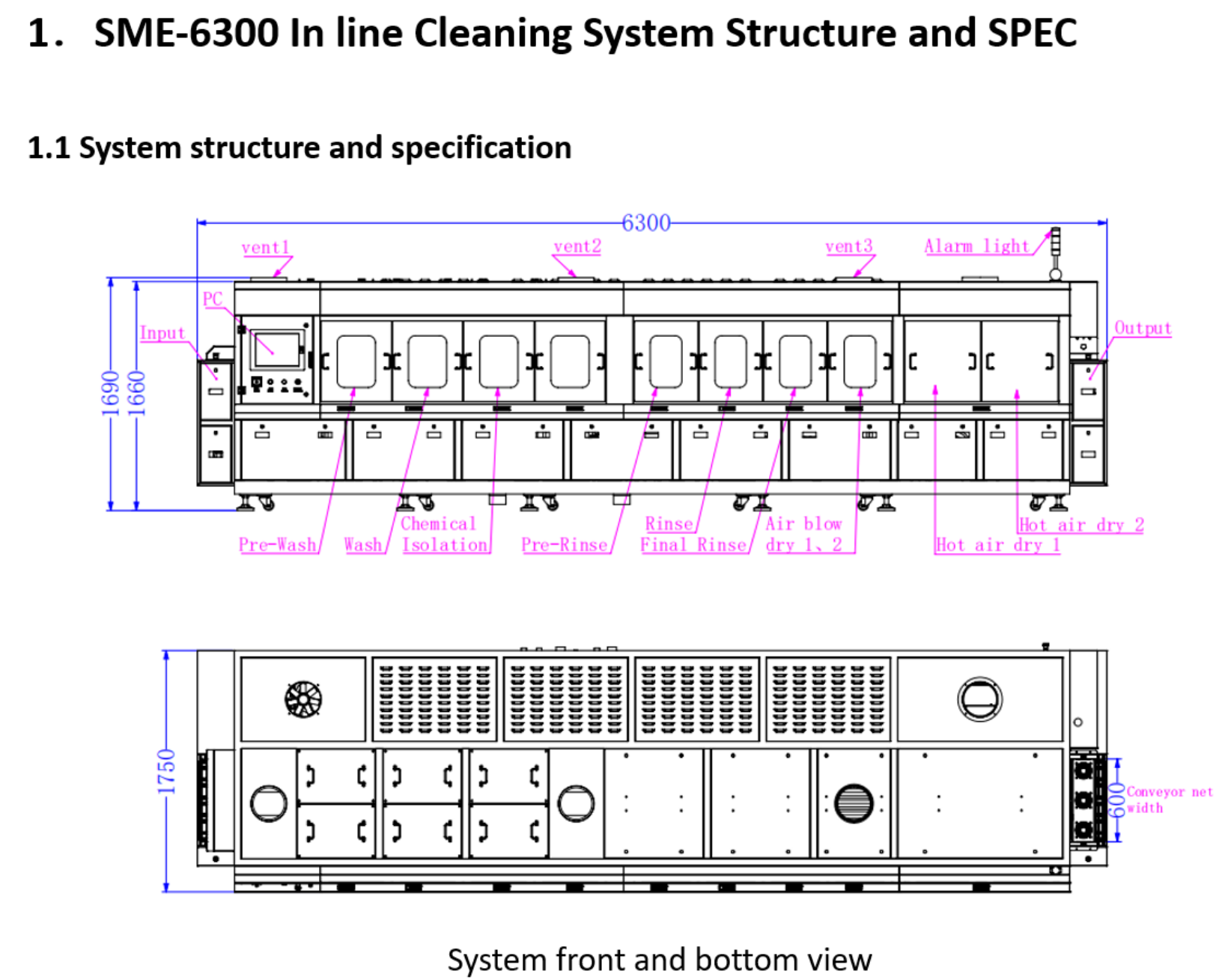

PCBA In-line Cleaning Machine-SME-6300

- Model

- SME-6300

Item specifics

- PCBA max size

- 600mm(W)X100mm(H)

Review

Description

PCBA In-line Cleaning Machine-SME-6300

Descriptions:

System Features

1 Stainless steel machine construction material and pipes, valves and manifolds.

2 PC+PLC control, Windows basic English operation software.

3 Prewash+Wash sections, spray pressure and angle of manifolds are adjustable.

4 2 condensation devices to cut chemical liquid cost to save liquid.

5 Standard concentrated chemical liquid tank.

6 Liquid temperature auto cooling system to maintain stable liquid temper.

7 Standard chemical isolation, air knives angle and blow pressure are adjustable.

8 Prerisne+ Rinse+ Final rinse sections, Spray pressure and angle of manifolds are adjustable.

9 DI water resistivity monitoring device on DI water supply pipe.

10 DI water input flow amount monitoring device on DI water supply pipe.

11 Digital pressure meters to monitor liquid/water spray pressure/air blow pressure.

12 Wash chemical liquid and DI water auto add and discharge air pumps.

13 Waste water auto discharge air pump.

14 Standard SMEMA signal line connection system.

15 MES system connecting software to monitor the machine status.

16 Energy saving function.

17 Inlet/outlet PCBA detecting sensors: PCBA quantity auto counting, PCBA time-out delay send out detecting...

18 Liquid and DI water leakage auto detecting and alarm function.

19 The body-to-ground resistance <1Ω, the body surface voltage <50V.

20 Power supply phase loss and phase sequence protection functions.

21 Over current and overload protection functions.

22 Current wave protection function at the time of machine starting.

23 Over-temperature protection function: liquid tank, water tank and hot air drying section

24 Liquid/water high level and low level protection function.

25 Emergency stop protection: emergency stop buttons on the inlet/outlet side, operation panel.

26 Chemical liquid concentration detecting and compensation device (Option).

Technical Specifications:

1. PCBA size: W600*T100(mm)

2. Conveyor net width: 600mm

3. Conveyor net speed: 0.1~1.5m/Min

4. Conveyor net direction: left to right

5. Conveyor net height: 920±25mm

6. Liquid temperature: RT~80℃

7. Prerinse DI water temp: RT~70℃

8. Rinse DI water temp: RT~60℃

9. Final rinse DI water temp: RT~40℃

10. Hot air dry temperature: RT~140℃(Special temp)

11. DI water supply: 6~15L/Min

12. Air vents: Φ250mm (3pcs)

13. Air volume: 42m³/Min

14. Total power: 159 KW

15. Power supply: AC380V, 3P, 50/60HZ, 300A

16. CDA supply: 0.5~0.7Mpa, 200L/Min

17. System length: L6300*W1750*H1700 (mm)

18. System weight: About 3600KG

Company Profile

About Samtronik

Samtronik is a professional one-stop SMT Equipment service provider , With more than 10 years Electronic Manufacturing Service factory Equipment selling experience .

Samtronik mainly supply pcb handling equipment ,PCB Separator ,screw locking machine , smt cleaning machine , smd counter , smd taping machine ,smt parts etc .